Australian projects face challenging environmental conditions that can damage ordinary steel within years. Coastal salt spray, industrial chemicals, and agricultural ammonia create the perfect storm for rapid deterioration and corrosion to occur. MAGNA-SHIELD PRO™ (MSP) changes the game for steel production in Australia. Instead of spending time planning replacement cycles, you can focus on building structures that last. Here’s what Australian engineers, architects, and project managers need to know about this top-tier coating technology.

PRODUCT BASICS

What is MAGNA-SHIELD PRO™ (MSP)?

MAGNA-SHIELD PRO™ (MSP) is a specially designed coating that protects steel against corrosion in Australia’s harshest conditions. Whether you’re dealing with coastal salt spray, industrial chemicals or agricultural ammonia, this coating keeps steel structures performing when other traditional coatings fail.

The coating combines zinc with 5% aluminium and 3% magnesium — a formula developed for Millform Australia’s MAGNA-SHIELD PRO™ (MSP). It meets AS 1397:2021 standards with ZM350 designation, which means it provides long-term protection versus traditional galvanised coatings.

What makes MSP special is its self-healing properties. When you cut or scratch the coating, the magnesium component activates to seal exposed edges and prevent corrosion from occurring. This makes MSP the practical choice for projects situated in environments prone to corrosion.

How does MSP compare to Z350?

MSP outperforms traditional Z350 galvanised steel by 3-5 times in corrosive conditions, thanks to its advanced coating technology. This performance advantage comes from extensive salt spray testing that follows ISO 9227, JIS Z2371 ASTM B117 standards using 5% NaCl at 35°C. While Z350 galvanised steel shows progressive corrosion damage over time, MSP ZM350 maintains its protective coating even after 4000 hours of continuous salt spray exposure.

Standard galvanising leaves exposed steel vulnerable the moment you make a cut. MSP’s self-healing properties protect these areas without requiring cold-gal sprays or touch-up treatments, saving both time and money during installation while delivering long-term protection. In fact, many builders in coastal regions have already been reporting significant savings in maintenance and replacement costs after switching to MSP.

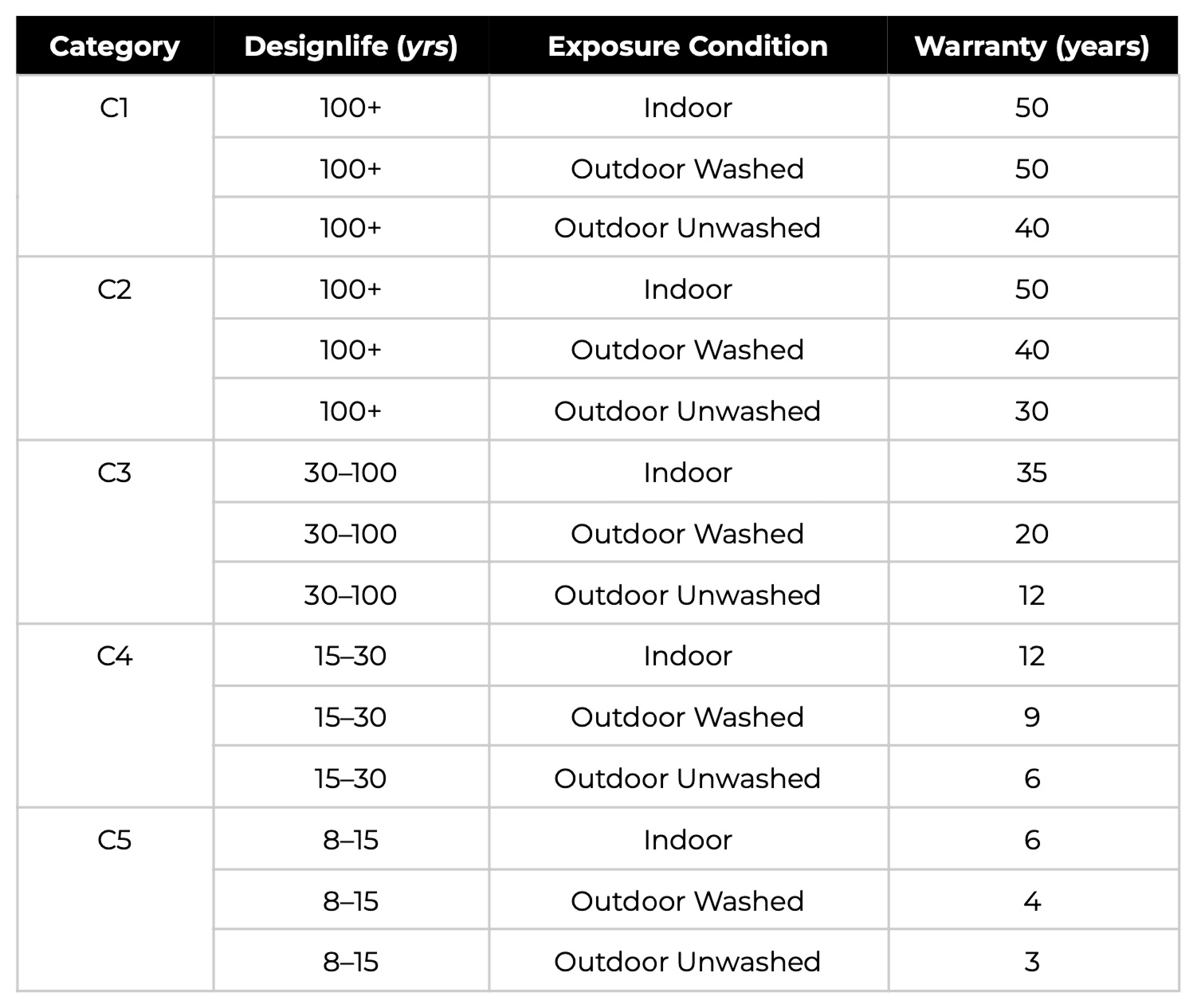

What is the warranty or expected lifespan of MSP?

In moderate inland environments, MSP is expected to perform satisfactorily with lifespans beyond 100 years. In harsher C4/C5 zones, typical lifespan ranges from 8-30 years depending on specific conditions like salt exposure and chemical contact. This figure is based on accelerated testing and performance data from similar coating technologies.

Warranty coverage varies by exposure conditions. Standard terms apply for C1 to C3 environments, while C4 and C5 applications require project-specific coverage. Millform’s technical team can work with you to determine the appropriate warranty periods based on your exact site conditions. If you’d like tailored warranty details for your project, contact our team for a quick assessment.

Contact our technical team to discuss warranty coverage for your specific project.

How quickly can you deliver MSP products?

Most orders ship out within 5-10 business days to anywhere in Australia. We provide delivery estimates upfront and have a strong track record of meeting delivery commitments, helping you avoid expensive project delays. Our Eastern Creek and Albury facilities keep production moving efficiently while maintaining the quality control MSP requires.

All profiles are pre-coated at the flat coil stage, before roll-forming into the final structural shapes. This integrated process ensures you get consistent coating coverage without the delays of post-manufacturing coating applications.

We understand that rush orders can happen, and we work with project teams to meet critical deadlines when possible. Early communication is key — let us know your timeline constraints upfront.

You can request a delivery estimate today to lock in your project timeline.

PERFORMANCE & APPLICATIONS

Is MSP suitable for all corrosive environments?

MSP performs exceptionally well across all corrosivity classifications from C1 through C5, including C4 environments (high-pollution industrial areas and substantial coastal exposure), which are some of the most challenging conditions for steel protection. The Australian Steel Institute’s corrosion guidelines show that corrosion costs Australia 2-3% of GDP each year. Getting material selection right from the get-go saves a lot of time and money.

C4 environments expose steel to constant salt-laden air and industrial chemicals that penetrate protective coatings and attack the underlying metal. Thanks to its zinc-aluminium-magnesium composition, MSP creates a barrier that withstands this damage. Where other galvanised products deteriorate easily, MSP protects your steel for a long time, eliminating the need for frequent maintenance work or complete replacement for years or even decades.

Not sure if MSP suits your environment? Our team can assess your site conditions and recommend the best approach.

Which environments are ideal for MSP use?

MSP is capable of handling various environments, but here are a handful where it’s best suited to use:

Industrial facilities with chemical exposure get the biggest benefit. Petroleum refineries, environmental labs, and manufacturing operations see dramatic improvements in equipment lifespan. The coating handles temperature swings and chemical exposure that destroys conventional protection.

Agricultural operations with ammonia and moisture problems find MSP invaluable. Feedlots, fertiliser storage, and intensive farming operations typically burn through galvanised steel quickly. MSP keeps working in these corrosive conditions.

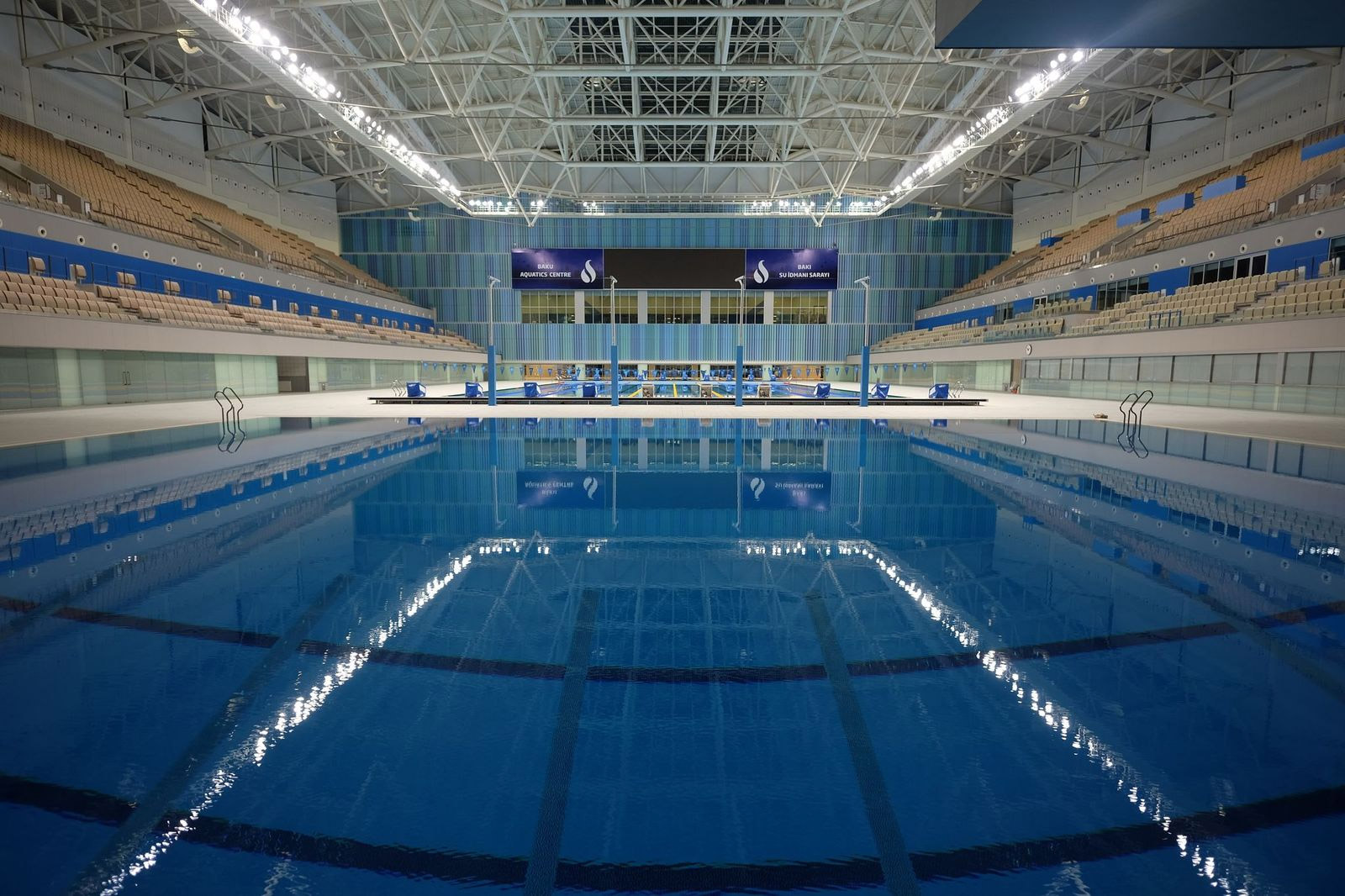

Coastal structures face constant salt attack. Marinas, jetties, and waterfront buildings show MSP’s salt resistance advantages clearly. Traditional steel often needs replacement within a decade near the ocean.

Inland high-salinity areas present unique challenges. Mining operations and areas with mineral-rich groundwater can be surprisingly corrosive. MSP handles these conditions where standard coatings struggle.

Chemical processing requires materials that won’t react with process chemicals. MSP’s stable coating prevents contamination while maintaining structural integrity through temperature cycling.

PRACTICAL CONSIDERATIONS

Are there special requirements when cutting MSP?

Heat damages MSP’s protective coating, so avoid angle grinders with cutting discs and plasma cutters. These tools create excessive heat that burns the coating and leaves steel exposed. Using proper cutting methods preserves MSP’s protective barrier, ensuring you get the full benefit of the coating.

Cold-cutting saws with tungsten carbide blades work best. They create clean cuts without heat damage. After cutting, file or grind away any rough edges that could trap moisture or chemicals. Smooth edges help maintain the coating’s protective barrier.

MSP’s self-healing properties take care of the rest. You don’t need cold-gal sprays or other touch-up treatments when you cut properly. This saves materials and labour while maintaining long-term protection.

Get in touch with us for detailed cutting guidelines and MSP handling best practices specific to your project.

Which profiles are available in MSP?

Millform produces most common structural profiles with MSP coating. CladForm™ Junction Studs handle façade connections, while our Archetype Purlin™ range covers C and Z-sections in both standard and down-turn lip configurations. For heavy-duty applications, Extreme Purlin™ sections provide additional load capacity.

Available profiles include:

- CladForm™ Junction Studs

- Trim Angles

- Archetype Purlin™ C & Z-Section Purlins

- Archetype Purlin™ C & Z-Section Down-Turn Lip Purlins

- Extreme Purlin™ C & Z-Section Purlins

- Brackets

- Channels

- HookFast® Purlin Bridging

This gives you a complete structural system with consistent corrosion protection across every component. No mixing different coating types or dealing with compatibility issues.

Can MSP be powder-coated or painted?

Why choose between form and faction when you can have both? MSP is fully compatible with powder-coating, allowing for limitless custom colour options. You can achieve the perfect aesthetic finish while further enhancing the up-to-100 years design life, in certain applications.

The surface preparation requirements match standard coating processes, so there are no special procedures that add costs. This flexibility matters for architectural projects where appearance and aesthetic count just as much as durability and quality. MSP is the smart choice for beautiful, resilient projects.

Looking to specify custom colours for your project? Ask about our powder coating compatibility and colour matching services.

SUSTAINABILITY & COMPLIANCE

Is MSP environmentally friendly?

MSP’s long service life cuts down on waste. Instead of replacing steel every 10-15 years, structures last decades longer. This reduces the raw materials needed over a building’s lifetime and cuts down on disposal waste.

The steel itself remains fully recyclable without any quality loss. When structures finally reach end-of-life, the material goes back into new steel production. MSP also reduces maintenance interventions, which means fewer chemicals, less transportation, and lower overall environmental impact from protective treatments.

Learn how MSP can help you meet your environmental targets while reducing lifecycle costs. Contact us today.

Ready to eliminate corrosion concerns?

Whether you need technical specifications, project-specific guidance, or pricing information, our experts will help you optimise material selection for Australian conditions.