MAGNA-Shield PRO™ (MSP)

Future-Ready Advanced Coated Steel

Longevity

Creating structures that stand strong for generations.

Innovation

Driving smarter designs and processes.

Legacy

Building with purpose, lifting the industry, and shaping the nation.

Build for Tomorrow™

Engineered for unmatched durability, MAGNA-SHIELD PRO™ (MSP)

sets a new benchmark in corrosion resistance and structural performance. With three to five times the lifespan of traditional galvanised products for a marginal cost increase, this advanced coated steel solution is built to withstand Australia’s toughest conditions while maintaining long-term reliability.

How It Works

MAGNA-SHIELD PRO™ (MSP) is designed with an advanced ZINC-ALUMINIUM-MAGNESIUM coating, providing superior corrosion resistance. Its unique self-healing properties protect cut edges, reducing maintenance costs and extending the lifespan of your assets. It is an ideal cost-effective alternative to stainless steel and aluminium due to its durability and performance benefits.

Unmatched Durability

- Engineered for three to five times

longer lifespan than traditional

galvanised products.

- Provides extended asset protection with only a marginal cost increase.

- Outperforms traditional hot-dip galvanised products in real-world applications.

Designed for Extreme Environments

- Built to withstand marine, ammonia, chemical, and industrial conditions.

- Ideal for Australia’s harshest climates, including high-humidity and high-salinity regions.

- Proven performance in aggressive industrial applications.

Superior Corrosion Resistance

- A unique blend of Zinc, 5% Aluminium, and 3% Magnesium provides outstanding protection.

- Self-healing properties on cut edges ensure long-term durability.

- Resists rust, oxidation, and degradation even in high-corrosion zones.

Ready to get started?

Tough Build, Tougher Materials:

Coastal Fertiliser Facility Built to Last

Spanlift Australia designed, engineered and developed a new 10,000 sqm facility in Cowell,

that faced harsh coastal conditions— MSP steel provided the durability and protection the site demanded.

Built for Harsh Conditions:

MSP Delivers for Spanlift Australia

With MAGNA-SHIELD PRO™ (MSP), Spanlift ensured a smoother build, enhanced finish and long-term corrosion resistance – ideal for the coastal, high-corrosion demands of fertiliser storage.

By selecting MSP, the project has been positioned for longevity, ensuring reduced maintenance costs and structural integrity well into the future.”

― Spanlift Australia

Have the same project in mind?

A Versatile Solution for Diverse Industries and Applications

Industrial and Commercial Projects

Agricultural and Horticultural Facilities

Marine and Aquatic Environments

Coastal and High-Salinity Areas

Chemical Processing Environments

Extended design life,

Less waste, Smarter building:

Touching the Earth, Lightly

Reduce replacements. Less maintenance. Cut carbon.

MAGNA-SHIELD PRO™ (MSP) delivers sustainability through superior design:

- Up to or even exceeding 100 years design life, in certain applications

- 3–5X lifespan vs. traditional galvanised steel

- No post galvanising required

- Engineered for Australia’s harshest environments

- 100% Recyclable at end-of-life

Performance with a purpose.

Capability Statement

Proven Performance

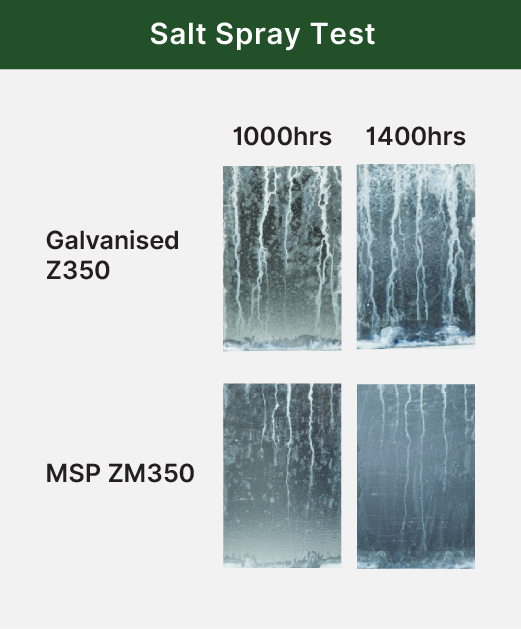

Salt Spray Test

- QTested to 4000+ hours of protection (ISO 9227, ASTM B117), ensuring superior resistance to corrosion and oxidation.

- Performance backed by rigorous laboratory and real-world testing.

Superior White Rust Resistance

- Inhibits the formation of zinc carbonate and hydroxide deposits.

- Ensures long-term surface durability and protection.

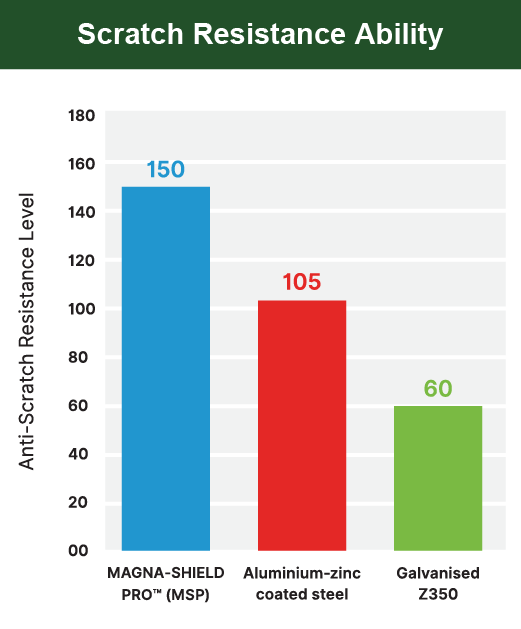

Enhanced Scratch Resistance

- QTested to 4000+ hours of protection (ISO 9227, ASTM B117), ensuring superior resistance to corrosion and oxidation.

- Performance backed by rigorous laboratory and real-world testing.

FAQ

It offers three to five times the lifespan, superior corrosion resistance, and self-healing properties on cut edges.

Yes, its unique composition withstands high-salinity exposure, ensuring long-term protection in coastal and marine applications.

Yes, it is easily powder-coated for enhanced aesthetics without compromising durability.

When the surface of the steel is scratched or cut, the reaction with moisture in the air combines with the coating to form a protective barrier that prevents further corrosion.

Yes, it maintains structural integrity and corrosion resistance in elevated temperatures, making it ideal for industrial applications.

It is typically and widely used in agricultural, infrastructure, industrial plants, commercial construction, water storage and coastal projects.

MAGNA-SHIELD PRO™ provides longer-lasting corrosion resistance, requires less maintenance, and eliminates the need for post-fabrication galvanising, reducing overall project costs.

Yes, its longer lifespan reduces material waste, and it does not require harsh chemical treatments for maintenance.

No, it can be handled like traditional coated steel products, with no additional processes needed.

MAGNA-SHIELD PRO™ is available in a range of product profiles with different dimensions and thicknesses to suit various applications. Contact us for specific options.

Let’s Get Your Project Moving

Send us your enquiry and we’ll get back to you with the info, specs, or support you need.

Fill in the form

We respect your privacy. View our Privacy Policy for details.

Get Started with MAGNA-SHIELD PRO™ (MSP)

Future-proof your assets with the next generation of advanced coated steel. Contact us today to learn more about how MAGNA-SHIELD PRO™ (MSP) can enhance your next project.